The Effective Procedure for Supplier Evaluation

Source: Alenia Aeronautica

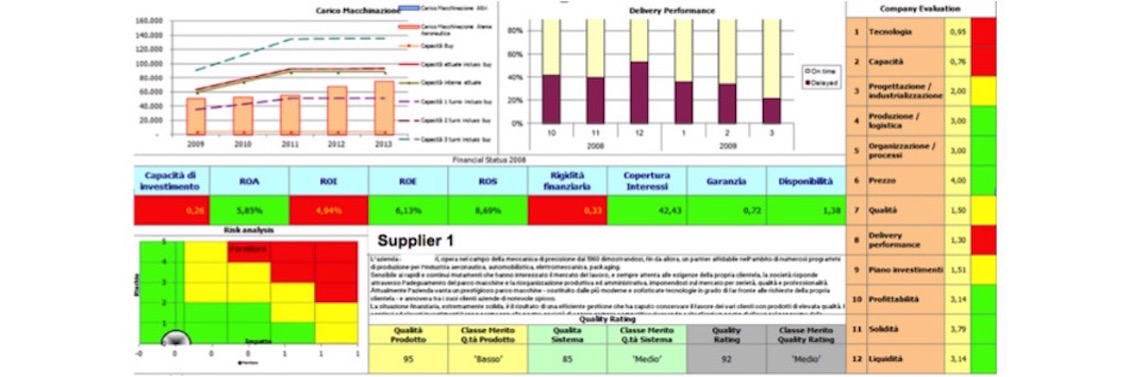

A Training Plan and a Methodology applied for an all-round Supplier Evaluation.

The favour with which Boeing and Airbus welcomed right from the beginning our method for the evaluation of supply chain capabilities and expertise encouraged us to develop an effective procedure and an integrated tool (repository), easy to use and available to all our users. Therefore, an essential part of the project is the diffusion of the methodology employed for vendor assessment process and for dedicated tool management and utilisation. So we developed a training plan for the resources involved in vendor assessment and in the use of the information obtained (e.g. allocation of new work packages). The most relevant role in vendor assessment will be played by users in the Supply Chain, Quality and Technology areas. The latter will be a material part during the entire process of planning, preparation, performance, development of assessment reports and identification of improvement actions; they will review vendors and contribute to their assessment and to the update of the information contained in the Repository. Their experience in the reference areas will guarantee the accuracy and consistency of the assessments as well as their continuous update. Procurement, Industrial Audit and Business Unit users will be the end users of the Repository: thanks to the information contained they will implement a continuing monitoring of the Supply Chain and check the status of each vendor in terms of performance, production capabilities, technology expertise and economic/financial standing.

This tool will help users in their duties and help them in making choices. It will also help monitoring the progress of the investment and improvement plans implemented by vendors for ”sustainability” and the feasibility of the work package entrusted or that are planned to be entrusted to them. In other words, the repository is not a database of “static” information, but a tool that will enable the continuing monitoring of each vendor’s present and future capabilities and expertise. Based on simulations, this tool will allow us to perform a “dynamic” check of production capabilities and to assume different work package allocation scenarios by introducing such variables as number of machine tool hours, type of materials or technology employed.

This tool will change our relationships with our vendors significantly. It will implement an all-round assessment supported by all the corporate departments involved, a detailed and careful review of vendor characteristics where vendors are no longer considered as passive entities subjected to the customer’s decisions but as active components of a partnership that privileges those vendors that understand the importance of this new form of relationship and can meet the challenges proposed by the market.

Cesare Travino

Procurernent & Supply Chain — Supply Chain, Budget

& Control Planning & Development

Tags: Supply Chain Management, Alenia Aermacchi, Company Assessment, Aerospace